Shinjin Machinery sticks to the top position

in the same business field.

Established in 1999, the corporate has grown up to be the biggest domestic manufacturer in JIG & APC business. Started with JIG and APC production in 2004, our consistently enhanced competitiveness reached the state of being unrivaled in domestic at present.

In 2008, the development of wire-cutting roller for manufacturing photovoltaic arrays was completed, and the products are exported to Japan today. The people of Shinjin Machinery, who thoroughly pursue the supremacy, try to satisfy customers by differentiating manufacturing processes on usage with all their might in every single step.

Based upon the movement to the new production line in Suwon City, Korea and the acquisition of Seoul Motec in 2014, Shinjin Machinery will make a leap forward as a more advanced global corporate.

Main item

Manufacturing of Main Roller 15%

Manufacturing of Valves 10%

Corporate Introduction

Corporate name : SHINJIN MACHINERY CO., LTD.

CEO : Hwan Sik Lee

Established : August 1, 1999

Capital : Three hundred million won

Affiliate company : SJM Co., LTD, Seoul Motec Co., LTD.

Main item : APC assemblies and JIG sets for processing auto engine parts, Precision processing, Main Roller, Friction welding machines.

Employees : About 40

Corporate History

The footprints of Shinjin Machinery from the establishment in 1999 to the present follow below.

1999 Established SHINJIN. Produced special purpose auto-parts-manufacturing machines. Produced friction welding machines.

2000 Developed camshaft friction welding machine.

2003 Credited for high precision technology for single-item processing by Komatsu-NTC of Japan(the world No.1 enterprise in producing the machine tools exclusively used for manufacturing various automotive parts such as engine, mission, etc.).

2005 Introduced two JIG boring machines from the Swiss company, DIXI, and three-dimensional measuring instrument(Germeany)

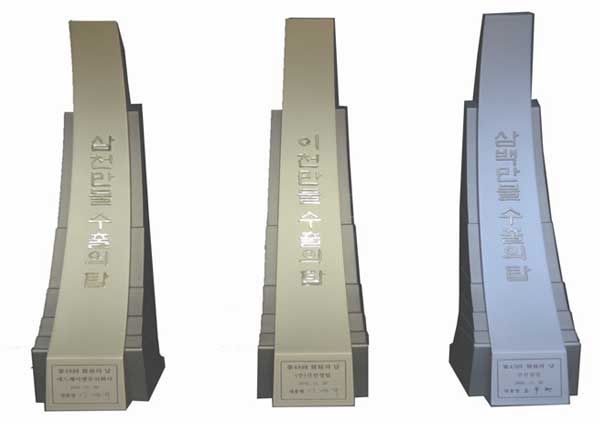

Awarded the Tower Order of Industrial Service Merit for achieving $3 million in exports.

2006 Constructed a new plant in Hwaseong-si, Gyeonggi-do, Korea. Converted to corporation.

Acrhieved $5 million in exports.

2007 Exported sillicon solar cells and main roller processed parts to Komatsu-NTC.

2008 Achieved 15 million dollars export sales of which items include single items, APCs, JIGs, main rollers and others.

2010 Started main roller processing and urethane businesses.

2011 Received the order of and delivered TOSHIBA MACHINE’s parts.

Awarded the Tower Order of Industrial Service Merit for achieving $20, $30 million in exports.

2012 Received the order of and delivered single items and JIG assemblies of YASUNAGA, ASIN TAKAOKA.

2013 Received the order of and delivered single items and JIG assemblies of NACHI FUJIKOSHI CORP.

Moved to the newly-built plant in Suwon-3-Industrial Complex, Gosaek-dong, Gwonseon-gu, Suwon-si, Gyeonggi-do, Korea(11,550m² of building site and 14,200 m² of building area).

Aquired SEOUL MOTEC(automotive intake·exhaust valves processing company).

2017 Introduced a JIG boring machine(YASDA-9150V, Japan) and a three-dimensional measuring instrument(ZEISS-ACCURA, Germany).

2018 Introduced a JIG boring machine(YASDA-8T, Japan) and two Flat type polishing machine(OKAMOTO, Japan).

2020 Introduced a JIG boring machine(MAKINO-v56i, Japan) and two CNC Lathe (Doosan-PUMA GT2600, Korea).

2021 Received the order of and delivered LOT-VACUUM’s HOUSING parts.

Introduced four JIG boring machine(DOOSAN-NHM6300, Korea / YASDA-7T, Japan) and a threedimensional measuring instrument(ZEISS-ACCURA, Germany).

2022 Introduced two JIG boring machine(DOOSAN-NHM6300, Korea)

2023 Introduced three JIG boring machineMAKINO-a81nx, Japan)

Partners

Shinjin Machinery is maintaining cooperative relationships with a variety of prominent companies in domestic and overseas such as Komatsu-NTC in Japan.